Racing is an expensive pastime. No two ways about that. That’s why, when I was presented with a need for two safety items by the AHRMA rulebook, I rooted around the garage before I slipped out my credit card. Luckily, I found two pieces of trash that solved my problems and will hopefully keep myself and the other racers on-track safe.

In 2022 I’ve been slowly chipping away at a big project: Building up another XR250R into a focused road-race bike. If that seems like an odd choice, it is. The motard class is exclusively comprised of dirt bikes with 17-inch wheels and street tires and is a downright fun class to run. The XR250R is an odd choice for this because though I race within a vintage racing organization, this class does not require machines to be of that aging quality, meaning the air-cooled thumper is often extremely outgunned. I tried it out last year as part of the Six Ways to Sunday project and got hooked even as a back marker. With suspension, wheels, and tires ready and sitting on the bench, I needed only everything else to assemble a race-ready bike. Thankfully, I had a shelf stacked with enough spares to make that that first build happen.

- A very rough starting point.

- A coat of paint goes a long way, plus some other repairs.

Said rack was comprised of just about any XR250 part or piece I could get my hands on for a reasonable price. A bare frame emerged, and the process started. I built the Six Ways to Sunday bike with little concern for appearance and a priority on performance. The second time around, I wanted a less scruffy build—one that showed the time that I put into it.

The process went pretty smoothly. (In other words, just behind schedule.) True to form, I am putting the finishing touches on the machine the week of the race event, this time an AHRMA race weekend at Blackhawk Farms raceway in Illinois. A few things slipped the last-minute order list, and suddenly building a safe, predictable bike came down to “figuring it out” with the things I had on hand.

I needed a catch can and belly pan but had nothing of the sort. What to do?

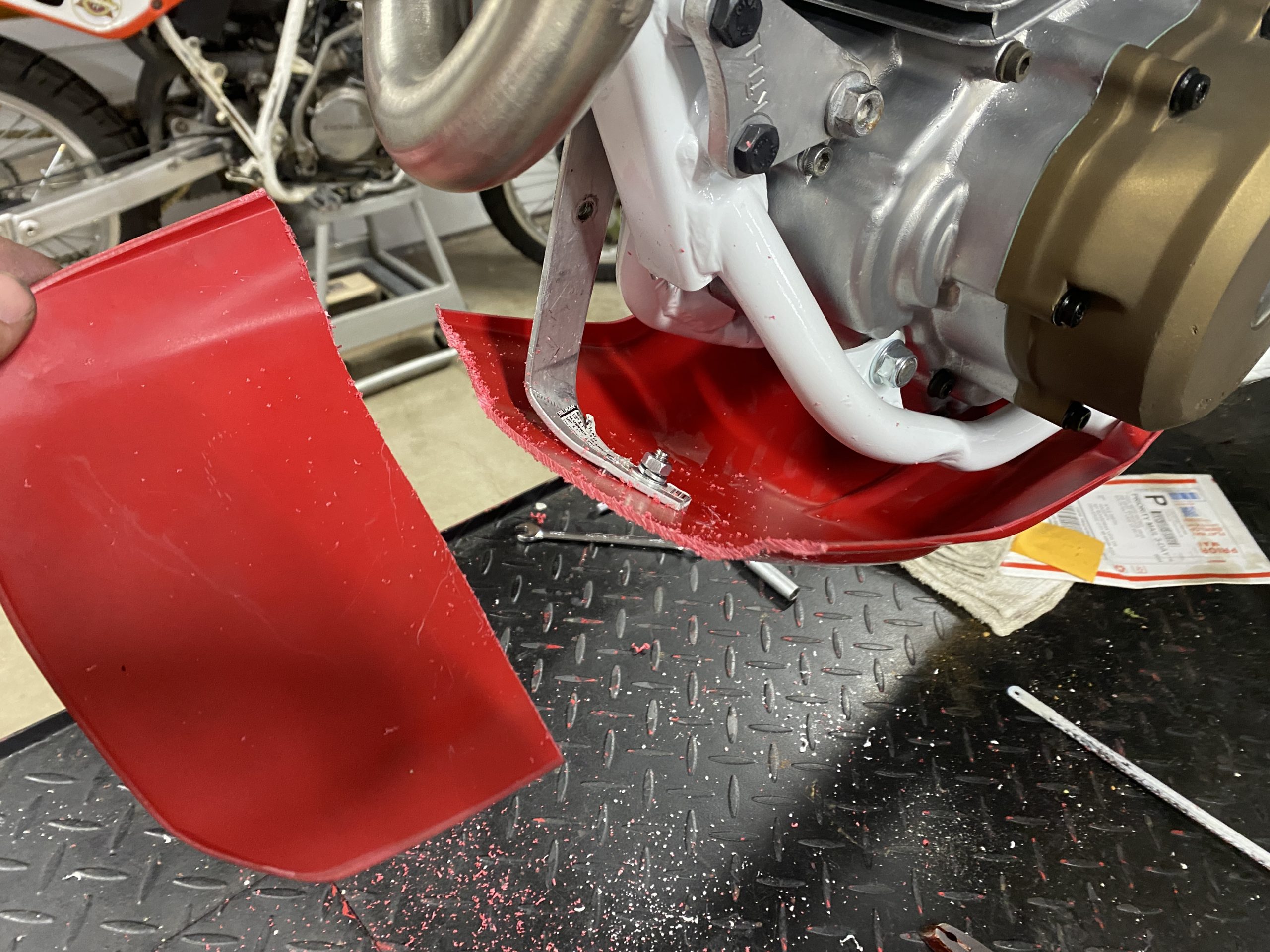

Some of you may recall that my solution to this exact problem last year was an aluminum baking pan, since this vintage Honda is not typically raced in this manner and thus lacks bolt-on parts support. That pan worked well, but this new XR is so much nicer it felt insulting to bolt that estate-sale dish to the bottom of the frame. I pillaged my shelves and found a rear fender I had ordered at some point and set aside when it arrived in the wrong color. It had a couple of bolt holes and a shape that could work—with some imagination. I have the latter. What I didn’t have was time or money.

On went the rear fender to the bottom of the XR chassis. I then went about hacking at with whatever sharp objects were within reach to refine the shape. It bolted on upside-down, which produced a natural, trough-type shape, but the nose extended too far upward and hit the exhaust. Cut here, trim there, drill a hole, and bend some scrap aluminum stock to hold the front of the belly pan in the right position. The rear just needed to be tucked up to the bracing just under the swing-arm pivot. The final step: Take a heat gun and heat the whole thing while it was bolted and zip-tied in place. This relaxed the plastic and conformed it to the new shape, making the whole thing easier to install and remove. A quick coat of paint followed, simply because I want this bike to match my other race bike.

- It fits. Sort of. Some cutting required.

- Nip off the leading edge so as to not interfere with the exhaust.

- The front edge needed a little sculpting to make it look right.

- A razorblade cleans up the edge to make it look finished and like it was never cut.

The belly pan prevents fluids that may be expelled during an engine failure from leaking onto the track and creating a hazard. Since my little 250 only holds 1.5 quarts of oil and no coolant, this pan doesn’t need to be very deep to fulfill that mission. The final product looks factory-fit except for that aluminum piece, but that’ll get re-done this winter.

- Normally I despise painting plastic like this, but in this case it will be just fine.

- With a couple stickers it looks like it was meant to be there.

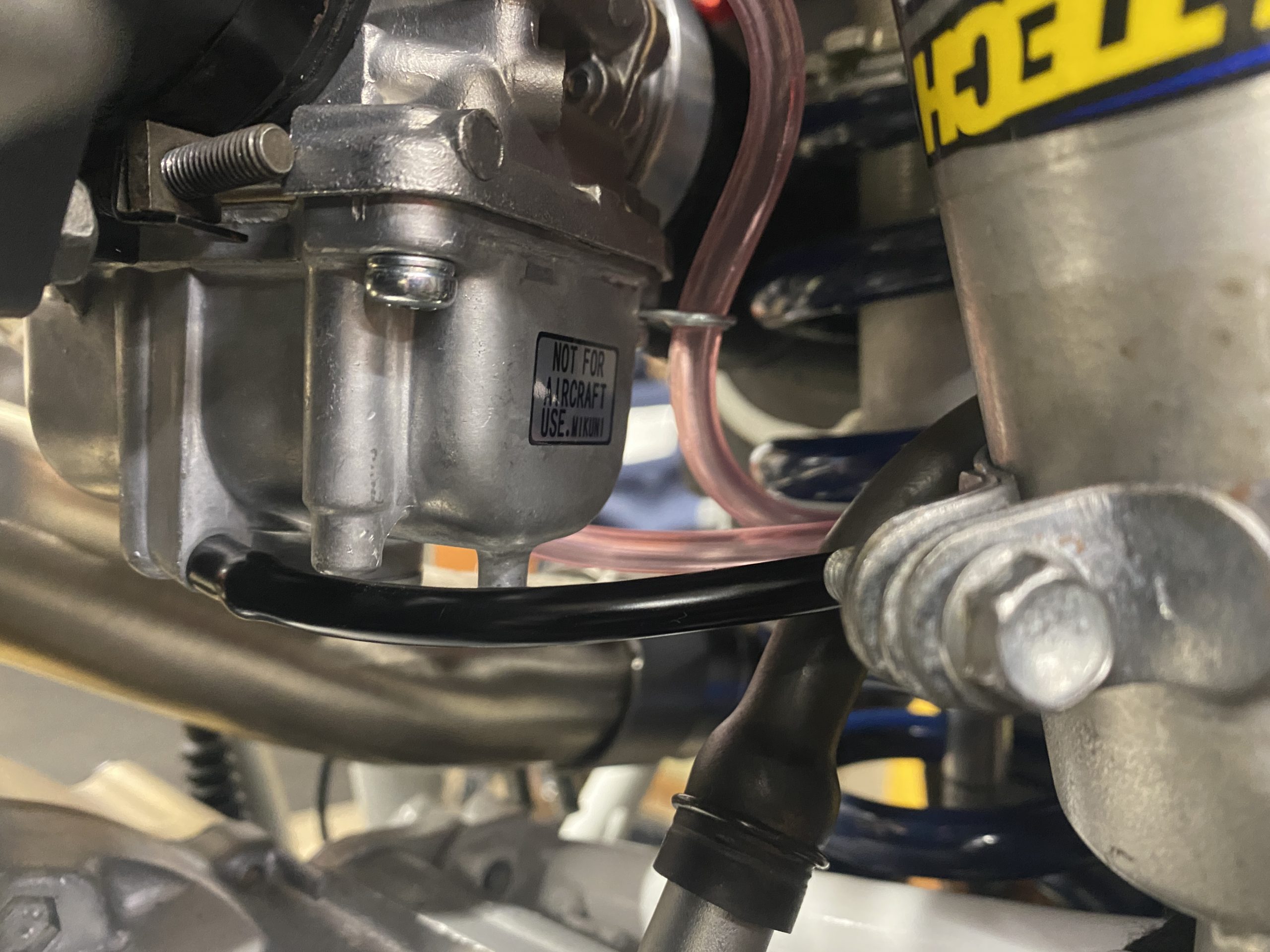

What doesn’t look original-spec is the other piece—the catch can.

One of the interesting and annoying things about carburetors and crankcase breathers is that they will happily puke out everything they can if they end up in an orientation other than the one for which they are designed. Can’t fault the parts, but if I were to experience a low-side, or any other accident in which my bike ended up lying on the track surface, the carb and case would drain onto the race surface without inhibition. Obviously a bad thing. A catch can prevents this by essentially routing the overflow and breather lines to one place, thus keeping the track surface clean.

- It’s a simple little can, but its light and appropriately sized for a catch can.

- Three holes to fit the three hoses coming off the carb.

One thing to remember: My XR250 races in a class that is open to all years of motorcycles. The top four places in any AHRMA motard race are Husqvarna FS450 machines, a purpose-built race model which left the factory with slicks. Its single-cylinder engine makes 63 hp from 450cc of displacement and the whole bike weighs in at a scant 240 pounds. My XR has nowhere near 63 horsepower—more like mid-20s, if I had to guess—and is close to 220 pounds as it currently sits. Adding more horsepower is expensive, but keeping weight to a minimum is fairly easy.

That’s why I grabbed a 6.5-ounce Starbucks Doubleshot can out of the recycle bin and zip-tied it to the frame. After carefully drilling a couple holes to keep the hoses tidy, I routed the large crankcase-breather through the opening that once allowed me to pour coffee into my face and used the pop-tab to keep that rubber hose in place. Sexy? No. Functional and light? Very much so. The fact it was free is just a bonus.

Two problems solved with a little bit of sweat and scavenging. Now, I can continue to lie to the missus about how affordable my hobby is. Pay no mind to the machine-shop bill, sweetie—look at how I repurposed this garbage! There is also the satisfaction of solving a problem with my brain rather than with my checkbook. That’s the takeaway here: Use your brain first, hands second, and financial resources third. I’m willing to bet you will be happier.